Valani Matailo Osasinthika a Ceramic Lining

Kufotokozera

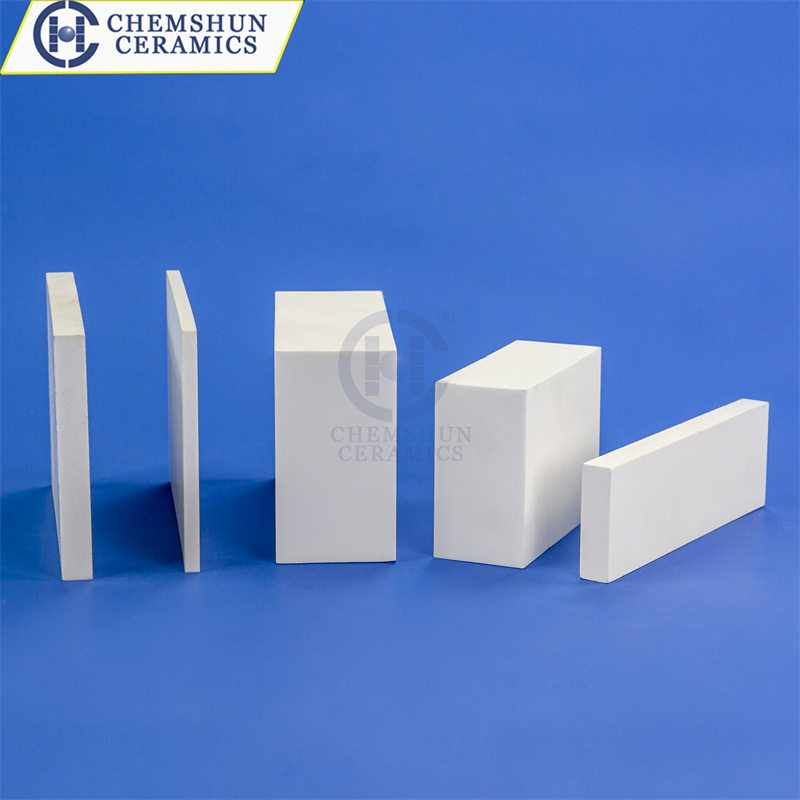

Matailo a Chemshun ceramic amathandizira ogwiritsa ntchito kuchepetsa nthawi yawo yocheperako komanso kukonza zokolola zawo. yokhala ndi ma geometries apadera, zidutswa zamitundu yowoneka bwino ndi zida zabwino kwambiri za abrasion zomwe zimakhudzidwa ndi pepala labala.Apa tikuwonetsa matailosi a chemshun alumina ceramic a Hopper, chute, mphepo yamkuntho, zitoliro za zitoliro ndi zina zambiri pazida zanu.

Alumina amavala tsiku laukadaulo la tile liner

| S. No. | Makhalidwe | Chigawo | Chemshun 92 | Chemshun 92 | Chemshun 95 | Chemshun ZTA |

| 1 | Zinthu za Alumina | % | 92 | 92 | 95 | 70-75 |

| ZrO2 | % | 25-30 | ||||

| 3 | Kuchulukana | g/cc | ≥3.60 | ≥3.60 | 3.65 | ≥4.2 |

| 4 | Mtundu | - | Choyera | Choyera | Choyera | Choyera |

| 5 | Kumwa Madzi | % | <0.01 | <0.01 | 0 | 0 |

| 6 | Flexural Mphamvu | Mpa | 270 | 300 | 320 | 680 |

| 7 | Density ya Moh | Gulu | 9 | 9 | 9 | 9 |

| 8 | Rock Well Hardness | HRA | 80 | 85 | 87 | 90 |

| 9 | Vickers Kuuma (HV5) | Kg/mm2 | 1000 | 1150 | 1200 | 1300 |

| 10 | Kulimba Mphwanyika (Mphindi) | MPa.m1/2 | 3-4 | 3-4 | 3-4 | 4-5 |

| 11 | Compressive mphamvu | Mpa | 850 | 850 | 870 | 1500 |

| 12 | Thermal Expansion Coefficient(25-1000 ℃) | 1x10-6/℃ | 8 | 7.6 | 8.1 | 8.3 |

| 13 | Kutentha kwakukulu kwa ntchito | ℃ | 1450 | 1450 | 1500 | 1500 |

Ntchito mu Industries

| Makampani | Zida dongosolo | Zida zida |

| Simenti | Pre-kusakaniza dongosolo la kugwa miyala yamchere ndi mafuta opanda mafuta | Mphepo yamkuntho, chotupa, chotupa, chotupa, chotupa |

| Yaiwisi mphero system | Dyetsani chute, mphete yotsekera, mbale yopukutira, mphete yosindikizira, mapaipi, chitetezo cha ndowa, chimphepo, thupi lopangira ufa, bunker | |

| Makina opangira simenti | Chute, bunker, fan vane wheel, fan casing, cyclone, duct yozungulira, conveyer | |

| Mpira mphero ndondomeko | Thupi la otulutsa mpweya ndi gudumu la vane, thupi la chotenthetsera ufa, payipi ya malasha ophwanyidwa, njira ya mpweya wotentha | |

| Sintering system | Kupinda kolowera/kutuluka, mbale yamtengo wamphepo, chimphepo, chute, chitoliro chotolera fumbi | |

| Afterheat system | Mapaipi olekanitsa ndi khoma | |

| Chitsulo | Yaiwisi kudyetsa dongosolo | Hopper, silo |

| Batching system | Kusakaniza bunker, kusakaniza mbiya, kusakaniza disk, disk pelletizer | |

| Sintered zinthu zoyendera dongosolo | Hopper, silo | |

| Dedusting ndi Ash discharge system | Kuchotsa mapaipi, bend, y-chidutswa | |

| Kuphika dongosolo | Chophika cha Coke | |

| Chigayo chothamanga kwambiri | Cone, ma buffles olekanitsa, chitoliro chotulutsira, mapaipi a malasha ophwanyidwa, chowotcha | |

| Mpira mphero | Kalasi, cholekanitsa chimphepo, bend, chipolopolo chamkati cha ufa | |

| Mphamvu yotentha | Njira yoyendetsera malasha | Makina oyendetsa ndowa, chopopera malasha, chodyera malasha, orifice |

| Mpira mphero ndondomeko | Chitoliro cha olekanitsa, chigongono ndi chulu, chigongono cha malasha ndi chubu chowongoka | |

| Chigayo chothamanga kwambiri | thupi la malasha, mabala olekanitsa, chulucho, mapaipi, chigongono | |

| Mphero yakugwa | Mpope wa malasha ophwanyidwa ndi chigongono | |

| Dedusting system | Dedusting's pipeline ndi chigongono | |

| Dongosolo lotulutsa phulusa | Chipolopolo cha fan duster, pipeline | |

| Port | Kunyamula zinthu dongosolo | Disiki yamakina a chidebe ndi hopper, chotengera chosinthira, chotsitsa chotsitsa, |

| Kusungunula | Kunyamula zinthu dongosolo | Choyezera choyezera, coke hopper, chute ya sikirini yonjenjemera, valavu yamutu, bin yapakatikati, bin ya mchira |

| Batching system | batch hopper, makina osakaniza | |

| Kuwotcha dongosolo | Chidebe cha phulusa, chubu cha calcine chopopera, hopper | |

| Dedusting system | Dedusting's pipeline ndi chigongono | |

| Chemical | Kunyamula zinthu dongosolo | Hopper, silo |

| Dedusting system | Dedusting's pipeline ndi chigongono | |

| Zida zopangira | Mzere wa Vibromill | |

| Malasha | Njira yoyendetsera malasha | Makina oyendetsa ndowa, chopopera malasha, chodyera malasha |

| Makina ochapira malasha | Hydrocyclone | |

| Migodi | Kunyamula zinthu dongosolo | Hopper, silo |

Utumiki

Timavomereza ma orders.

Ngati mukufuna kudziwa zambiri zamalonda, chonde omasuka kulankhula nafe ndipo tidzakupatsani mankhwala abwino kwambiri ndi ntchito yabwino kwambiri!