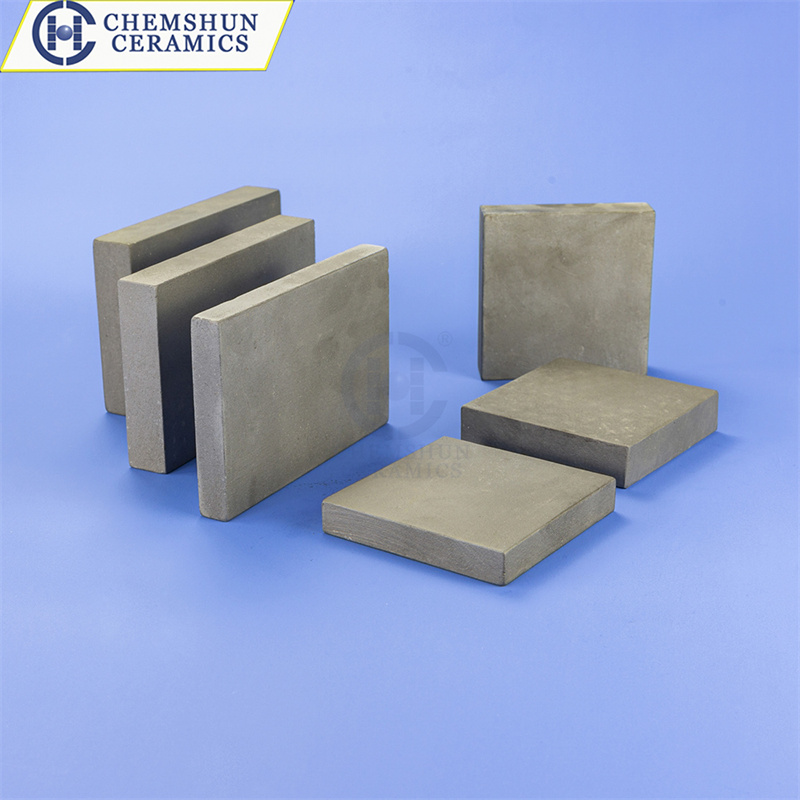

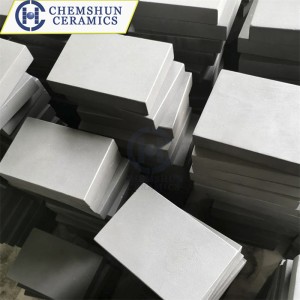

Rection Bonded Silicon Carbide Tile

Ubwino wa Reaction Bonded Silicon Carbide

1) Kutsika kochepa.

2) Kukana dzimbiri.

3) Valani kukana.

4) Kukana kwa okosijeni.

5) Kukana kwa abrasion.

6) Kukana kwabwino kwa kutentha kwamafuta (chifukwa cha kuchepa kwamafuta owonjezera komanso kutsika kwamafuta).

7) Mphamvu Zabwino Kwambiri pa kutentha kwakukulu.

8) Kuwongolera kwabwino kwa mawonekedwe ovuta.

Valani Zinthu Zosagwirizana: Silicon carbide mbale, Silicon carbide njerwa, Chitoliro cha chitoliro, Pipe Cone, chimphepo, etc.

Mipando yamoto: Plate, Beam, Roller, Burner Nozzle, Round mtengo, lalikulu lalikulu, bowo.Crucible, Sagger, etc.

Zina: Mipumi ya desulfurization

Kugwiritsa ntchito Reaction Bonded Silicon Carbide:

Rection bonded silicon carbide yatsimikizira kuti ndiyabwino kwambiri pazovala ngati zomangira mapaipi, Nozzles, kutsokomola kowongolera ndi zida zazikulu zovala mumigodi komanso mafakitale ena.

Main Parameter

| Katundu | Mayunitsi | SiSiC/RBSIC |

| Kuchulukana kwakukulu (SiC) | V01% | ≥85 |

| Kuchulukana kwakukulu | g/cm3 | 3.01 |

| Zowoneka porosity | % | <0.1 |

| Modulus yophulika pa 20 ℃ | Mpa | 250 |

| Modulus yophulika pa 1200 ℃ | Mpa | 280 |

| Modulus ya elasticity pa 20 ℃ | Gpa | 330 |

| Kulimba kwa fracture | Mpa*m1/2 | 3.3 |

| Thermal Conductivity pa 1200 ℃ | wm-1.k-1 | 45 |

| Kukula kwamafuta pa 1200 ℃ | ndi ×10-6/℃ | 4.5 |

| Thermal shock resistance pa 1200 ℃ | Zabwino kwambiri | |

| Coefficient of heat radiation | <0.9 | |

| Kutentha kwakukulu | ℃ | 1350 |

Kukula

akhoza kusinthidwa malinga ndi zofuna za makasitomala.

Utumiki

Timavomereza ma orders.

Ngati mukufuna kudziwa zambiri zamalonda, talandiridwa kuti mutilankhule ndipo tidzakupatsani mankhwala oyenera komanso ntchito yabwino kwambiri!